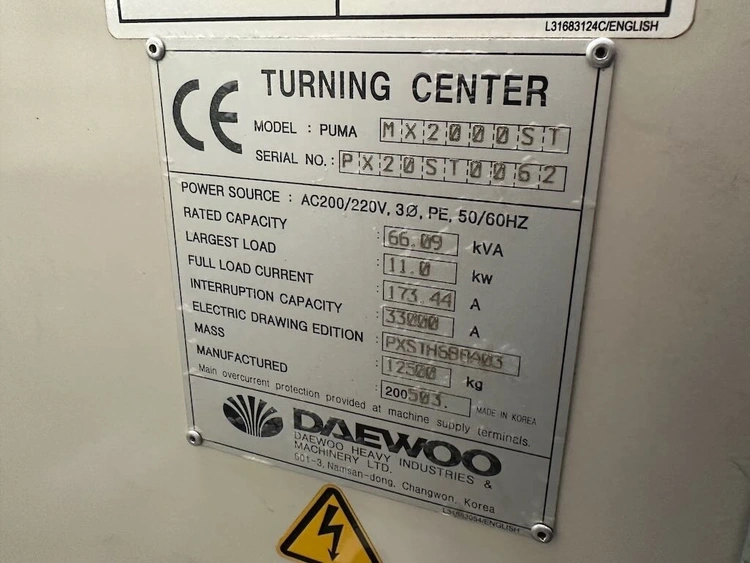

USED 2005 DAEWOO PUMA MX2000ST with 8 controlled axes plus an A-axis programmable tailstock

Overview

- Type

- CNC Lathes

- Manufacturer

- DAEWOO

- Model

- PUMA MX2000ST

- Year

- 2005

- Status

- for sale

Description

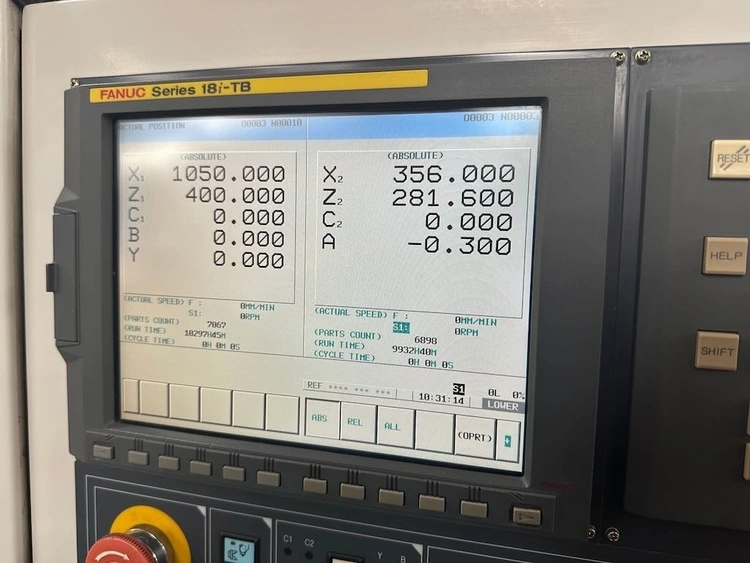

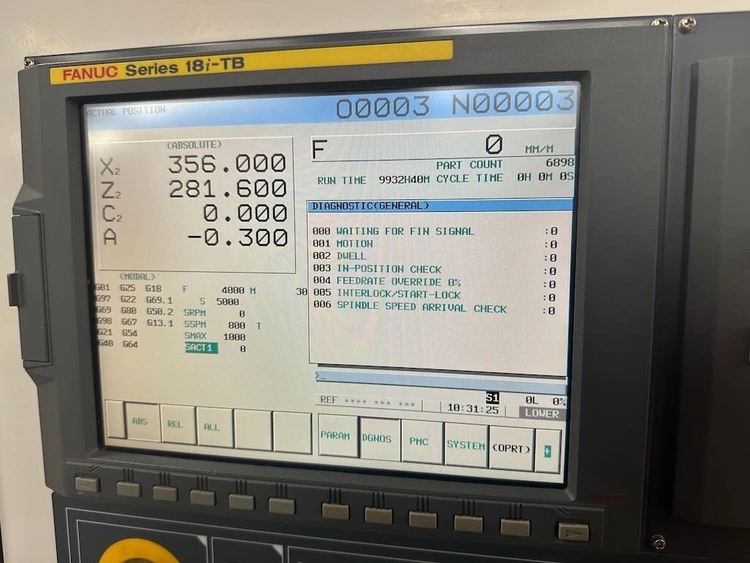

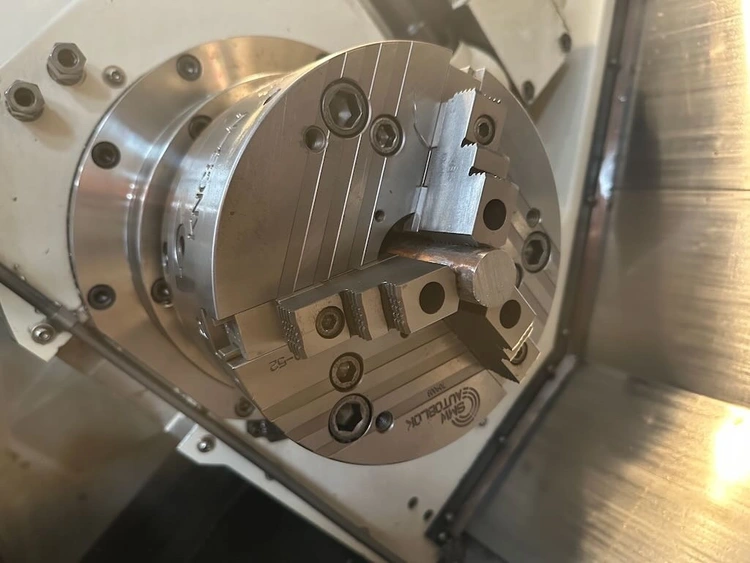

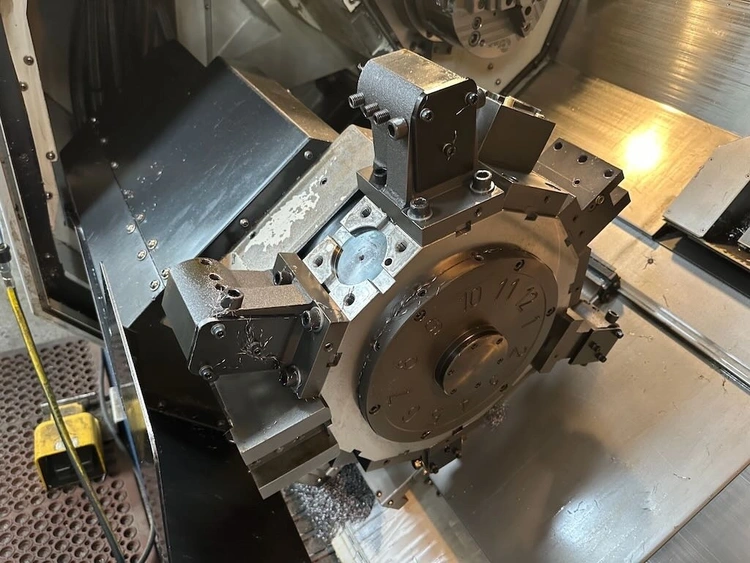

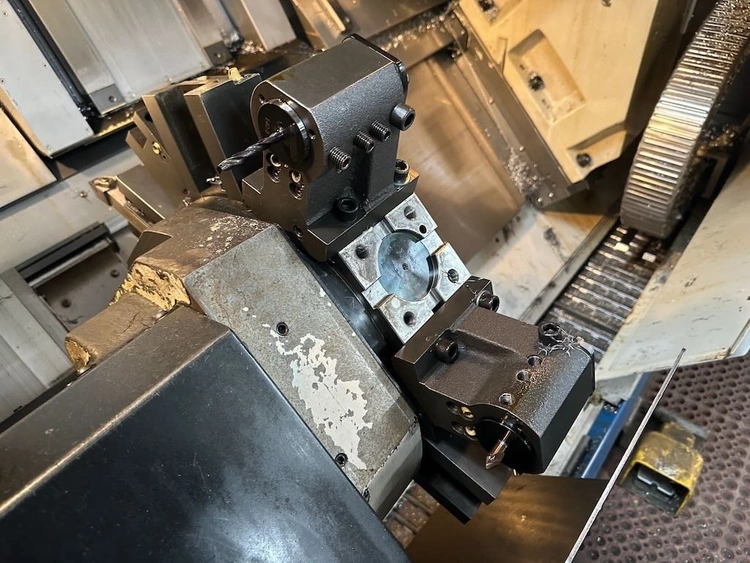

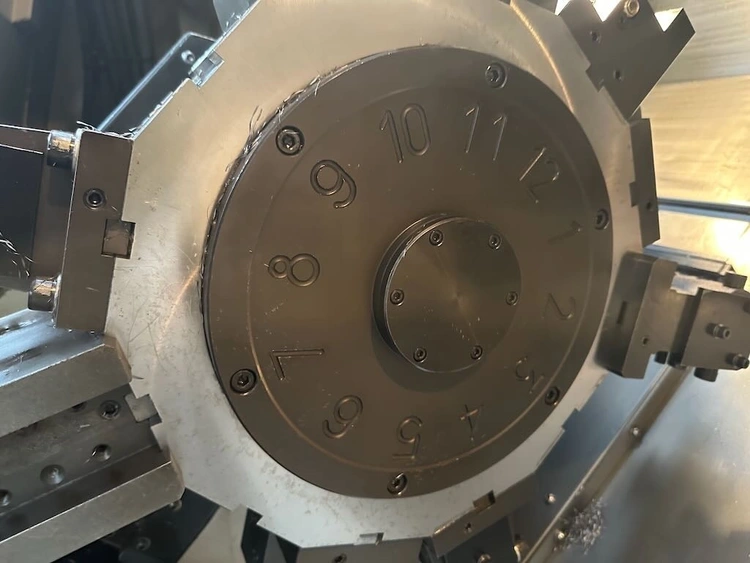

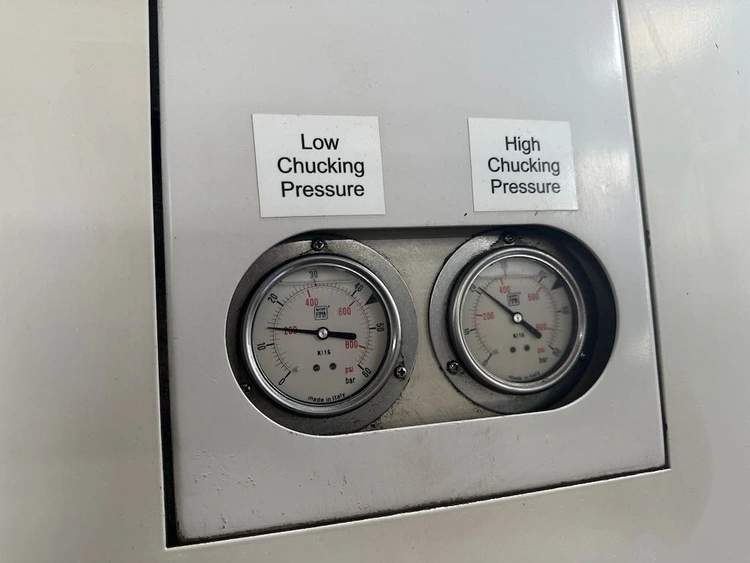

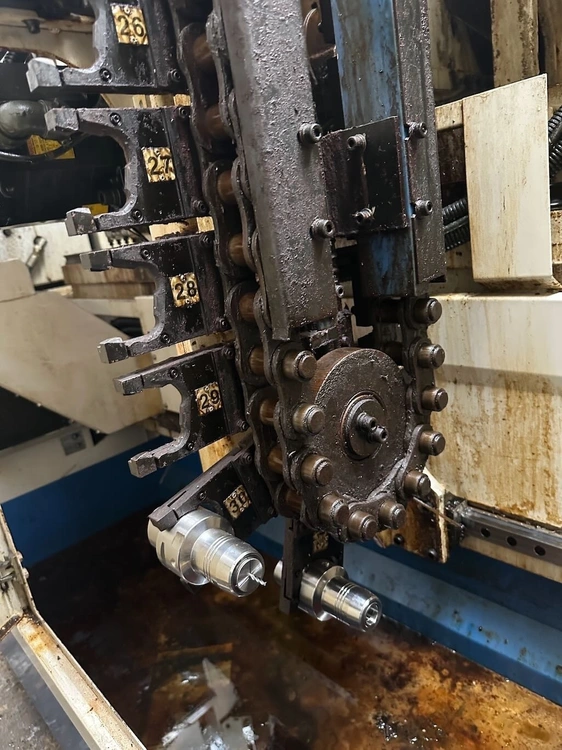

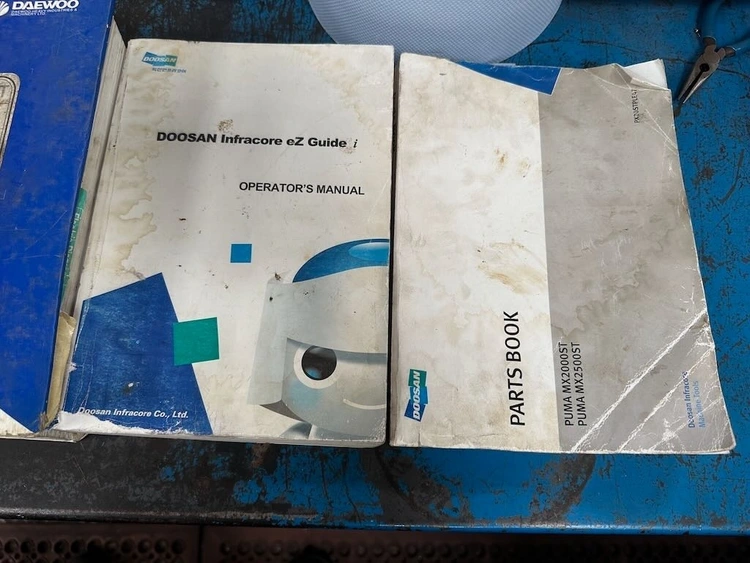

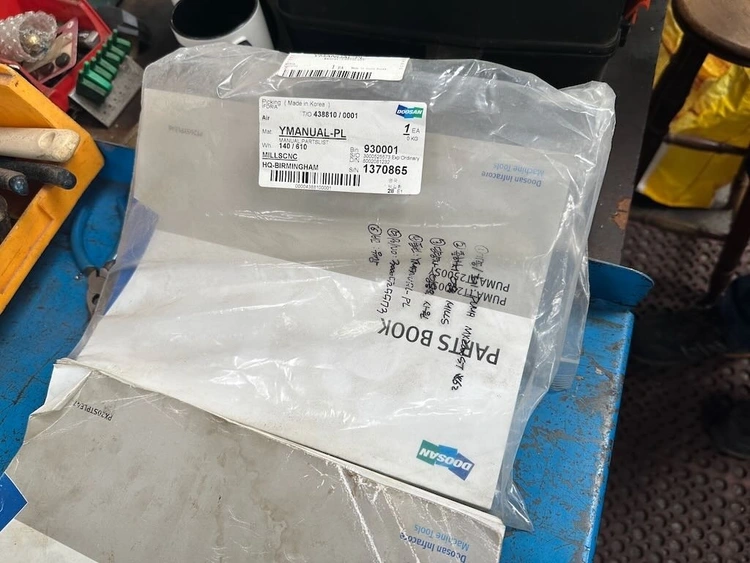

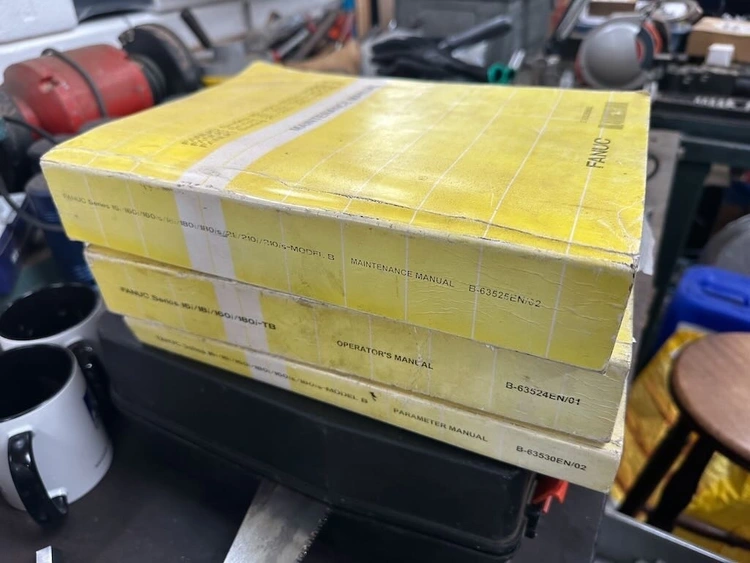

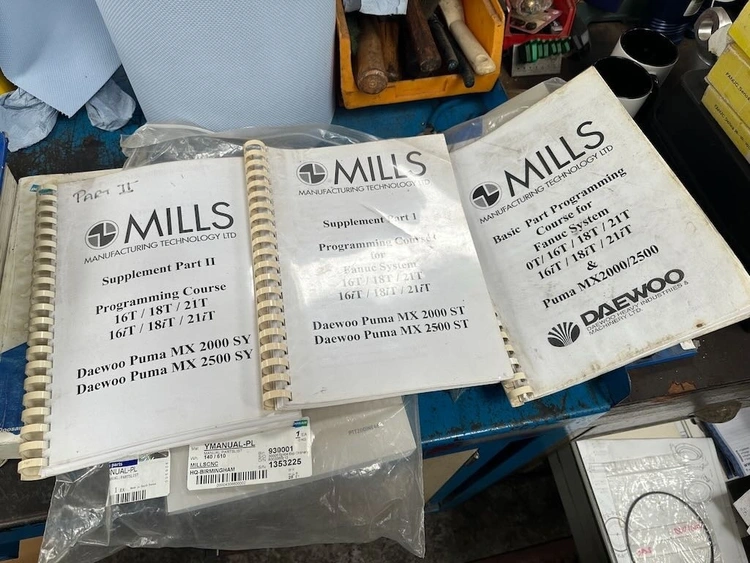

2005 Daewoo Puma MX2000ST — Multi-Axis Mill/Turn Centre The Puma MX2000ST is a powerful multi-tasking CNC centre designed to combine turning and milling operations in a single setup. Equipped with twin spindles and a lower turret, it allows simultaneous machining for improved productivity. Key features include: Twin spindles with C-axis control Maximum turning diameter approx. 550 mm, turning length approx. 1,020 mm 9 controlled axes for complex machining Live tooling with automatic tool changer Fanuc CNC control system Rigid build for accurate, heavy-duty machining A versatile solution for high-precision work, ideal for reducing setup times and handling complex components in one machine. Programmable tailstock (A-axis) • Hi-Pressure Through-spindle coolant • Parts catcher and conveyor • LNS FOX2000 Filtermist unit • Tooling package • Full documentation and manuals

Specifications

| Swing | 29.5276" |

| Machining Length | 40.1575" |

| # Axis | 8 |

| Chuck Size | 8" |

| Bar Capacity | 2.55906" |

| Power | 40.2106hp |

| Max RPM | 5000rpm |

| Turning Dia | 21.6535" |

| Tailstock | 'Yes' |

| Live Tooling | 'Yes' |

| Sub Spindle | 'Yes' |

| Control | CNC (Fanuc 18i-TB) |

| Dimensions | 177.953 x 98.2677 " |

| Weight | 12,500 kg |